Modular construction and prefabricated systems are reshaping the building industry. Far from being a passing trend, they represent a structural transformation in how we build, faster, more precise, more sustainable, and highly scalable. This article explores the growth outlook for the sector in Europe and Spain from 2025 to 2030, the key drivers behind this expansion, and the unique role of technologies like EvoConstructor®.

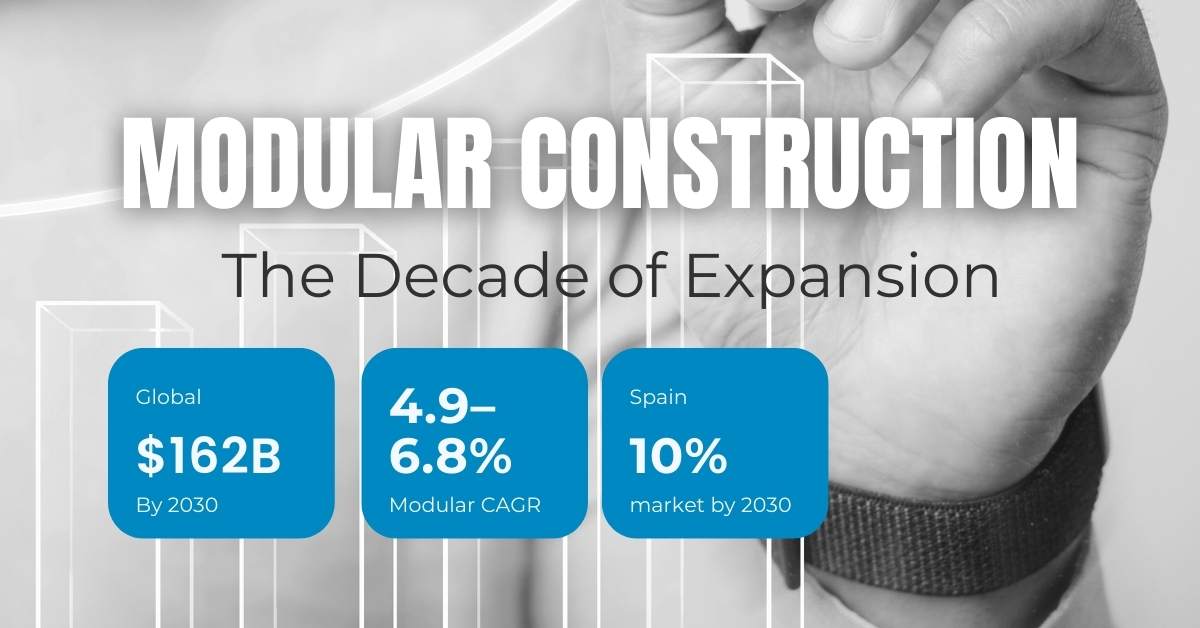

A Growing Market: Key Data for Europe and Spain

Europe:

- The modular construction market is projected to grow from USD 20.5 billion (2025) to USD 30.9 billion (2032).

- Estimated CAGR: 6.1%.

Spain:

- The prefabricated building segment will grow from USD 3.49 billion (2024) to USD 4.69 billion (2029).

- Estimated CAGR: 6.13%.

- By 2030, industrialized construction could account for 10% of the residential market.

Source: Mordor Intelligence, Statista, ANDECE.

This sustained growth reflects a transformation in Europe’s construction model, with rising demand for solutions that offer speed, predictability, and sustainability in both public and private projects.

Growth Drivers

Market Needs

- High demand for fast, scalable solutions in housing, offices, and public infrastructure.

- Projects increasingly require tighter control over cost and timelines.

Regulatory and Environmental Pressure

- Standards like ISO/ASTM 52939:2023 encourage low-carbon construction models.

- Incentives for industrialized processes due to their energy efficiency.

Enabling Technologies

- Advances in robotics, on-site 3D printing, and BIM.

- Real-time quality control and full process traceability.

⚠️ Challenges to Overcome

Despite its enormous potential, modular construction still faces barriers:

- Industrial Scalability: Many plants must upgrade to meet demand using automated, interoperable systems.

- Tech Interoperability: Integrating BIM, robotics, planning software, and regulations demands a robust digital infrastructure.

- Market Perception: Prefabrication is still wrongly associated with low quality or repetitive designs.

- Advanced Logistics Management: Coordinating digital design, transport, and on-site assembly requires extreme precision.

- Compliance Complexity: Component validation with both local and international standards is challenging without automation.

EvoConstructor®: Driving the Industrialization of Construction

EvoConstructor® is the technological answer to these challenges. Its multifunctional, internationally patented design enables:

- Automation of critical tasks such as structural 3D printing, concrete pumping, leveling, finishing, and self-elevation.

- Integration with both prefabrication plants and on-site projects, adapting to diverse operating conditions.

- BIM and management platform connectivity for full process traceability.

- Standards compliance, including ISO/ASTM 52939, ensuring certified workflows.

- Methodology replication across projects, minimizing learning curves and risks.

Measurable Impact in Prefab Projects

| Indicator | With EvoConstructor® |

|---|---|

| Execution time | ↓ up to 50% |

| Operating costs | ↓ up to 10% |

| CO₂ emissions | ↓ up to 20% |

| Customization | Full, from initial design |

| Rework and errors | 0 manual corrections |

| Material optimization | Continuous improvement |

| Supervision | Remote, real-time |

This unique mix of precision, automation, and sustainability makes EvoConstructor® a key tool for scaling modular production without sacrificing design or compliance.

Modular Construction in 2030: What to Expect

Looking ahead to 2030, modular construction will be fully integrated into the sector’s value chains:

- Full digitalization from generative design to robotic assembly.

- On-demand production based on real-time data.

- Plug & build systems with integrated utilities.

- Full decarbonization using sustainable materials and zero-emissions processes.

- Hybrid models blending in-situ and off-site construction through technologies like EvoConstructor®.

This vision is not futuristic, it’s already underway with tangible solutions like those Evocons brings to market.

Conclusion: A Decade to Lead the Transformation

Industrialized construction is not optional, it’s a necessity. The numbers speak for themselves, and technologies like EvoConstructor® are making it possible. Companies adopting these models will be better positioned to lead in productivity, sustainability, and regulatory compliance.

Want to scale your modular production with robotics?

Book a demo with our technical team today.

If you’d like, I can now move on to delivering the SEO-optimized post, metadata, LLM-ready blocks, and strategic clustering/editorial planning based on this translation. Would you like me to proceed?